Products

-

Best Energy Product

3D Print Filament

3D Print Filament

Water-resistant and eco-friendly

polypropylene (PP) material -

-

3D Print Filament Description

Filament for 3D printing is a new product line of Best Energy. Just like ink is used in normal printing, 3D printing uses a dedicated filament. Filaments are classified according to the plastic material used in manufacturing, and there are ABS, which is easy to sand and paint, PLA, which has good practicality and stability, TPU, which uses rubber, and PETG, which supplements ABS and PLA.

Currently, Best Energy is producing filaments for 3D printing made of PLA material, and is researching and developing filaments made of polypropylene (PP), which are strong against moisture and eco-friendly, unlike existing materials.

-

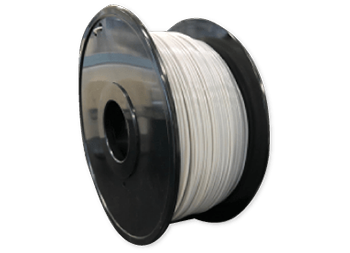

PLA filament FilG

with good adhesion

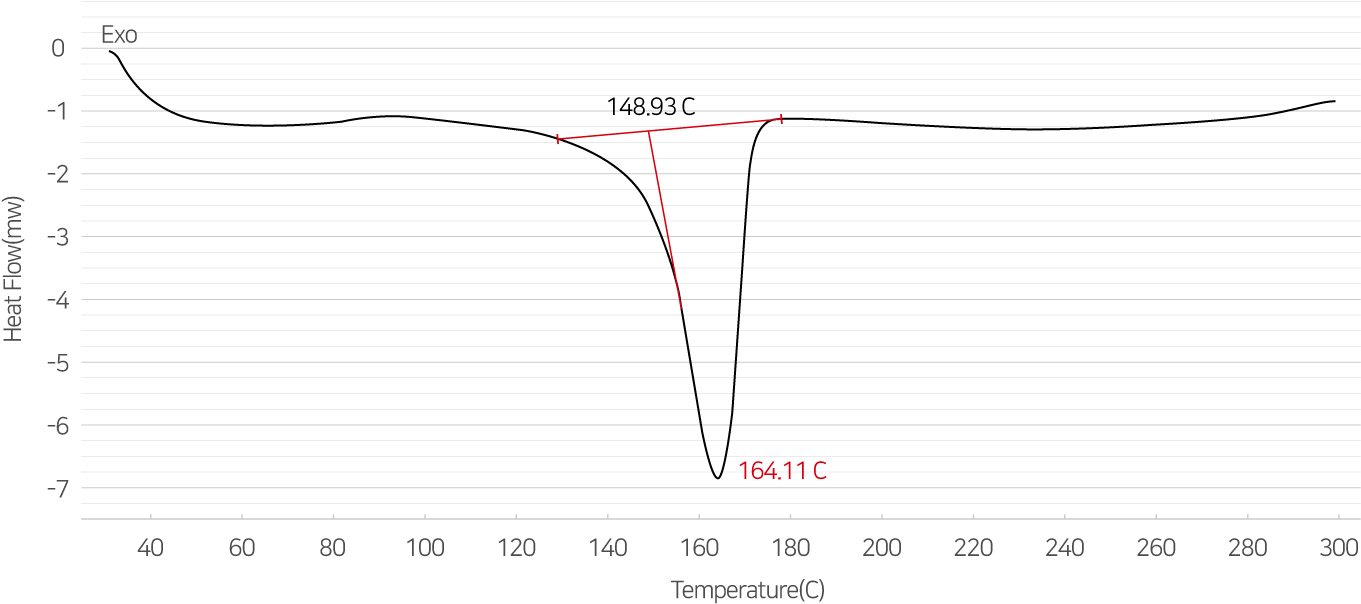

and easy coolingBest Energy has created an improved product compared to PLA filament in the existing market based on its experience in R&D of polymer materials. Best Energy's PLA filament FilG has a higher viscosity than existing products, so it has the advantage of being easily seated on the bed (appropriate bed temperature 55~60℃). In addition, it melts well at a relatively low temperature of about 190℃, so it is easy to cool, so it is suitable for personal 3D printing work.

-

Moisture-resistant and eco-friendly polypropylene(PP) filament

Both ABS and PLA materials, which are the most used in 3D printing filaments, have the disadvantage of being weak against moisture. To solve this problem, Best Energy is conducting research on making polypropylene(PP) materials into filaments.

-

Because polypropylene material is strong against moisture, it is not necessary to maintain humidity during filament storage and thread use, and at the same time, it has the characteristic that harmful substances do not come out.

Best Energy intends to present a new paradigm in the existing filament market by commercializing polypropylene filament. -